Proton Products InteliSENSTM CG series capacitance gauges are designed for the continuous measurement of cable insulation capacitance on insulation extrusion lines, enabling manufacturers to control the capacitive characteristics of their cable insulation.

Proton Products InteliSENSTM CG series capacitance gauges are designed for the continuous measurement of cable insulation capacitance on insulation extrusion lines, enabling manufacturers to control the capacitive characteristics of their cable insulation.

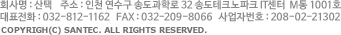

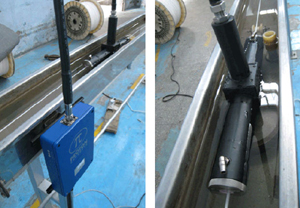

Capacitance gauge heads are available to accommodate different cable diameters and are designed to be immersed in the post-extrusion water cooling trough. For applications which do not use a water trough, high-pressure water may be injected into the capacitance gauge head to jacket the cable in water; ceramic lined end-caps are available for sealing smaller diameter cables.

The rugged, compact and durable design, multiple communications options and easy integration with other systems make the InteliSENSTM CG Series an excellent and economical choice.

The cable runs through the InteliSENSTM CG capacitance gauge head which is connected to the InteliSENSTM CAP interface box signal processing unit which analyses the capacitance measurement using an advanced auto balancing bridge system, with sophisticated FPGA processing to ensure drift-free capacitance measurement.

The InteliSENSTM CG Series gauge head is supplied with an IP65 rated InteliSENSTM signal processing unit (CAP interface box) and a 1.5m long industrial interconnection cable. On PLC or computer controlled productions lines, the CAP interface box can communicate directly via RS232. Optional PROFIBUS or Ethernet/IP communications interfaces may also be specified at time of order placement.

An optional NEXiSTM CS2G-CAP stand-alone interface display and PI feedback control unit is available as an accessory for the CG series capacitance gauges. The NEXiSTM CS2G-CAP interfaces via CANbus to any InteliSENSTM CG system CAP interface box to drive insulation extruders or capstan drives to control insulation capacitance. The NEXiSTM CS2G-CAP also provides a pair of analogue voltage outputs representing capacitance and capacitance error and 3 relay outputs for signaling out of tolerance capacitance.

Specification | CG1010 | CG1025 | CG1050 | Units |

|---|---|---|---|---|

| Maximum cable diameter | 10 | 25 | 50 | mm |

| Gauge head bore diameter | 15.1 | 30.1 | 75 | mm |

| Overall gauge head length | 410 | 630 | 1080 | mm |

| Active electrode length | 155 | 140 | 140 | mm |

Specification | Minimum | Typical | Maximum | Units |

|---|---|---|---|---|

| Capacitance | 0 | 500 | pF/m | |

| Accuracy | -0.2 | 0.2 | % | |

| Gauge head to CAP interface box cable length | 1.5 | m | ||

| CAP interface box weight | 2.5 | kg | ||

| Power supply voltage | 11 | 24 | 25 | VDC |

| Power consumption | 12 | W | ||

| Operating temperature | 5 | 45 | °C | |

| Gauge head environmental protection | IP67 | - | ||

| CAP interface box environmental protection | IP65 | - |

| Standard communications interfaces | CANbus | RS-232 |

| Optional communications interfaces (to be specified at time of ordering) | PROFIBUS | Ethernet/IP |